Fleet operations have always depended on one basic principle: keep vehicles running reliably for as long as possible. For decades, fleet managers relied on experience, fixed service schedules, and manual inspections to maintain their vehicles. While this approach worked in the past, growing fleet sizes, tighter margins, and higher safety expectations have made it less effective.

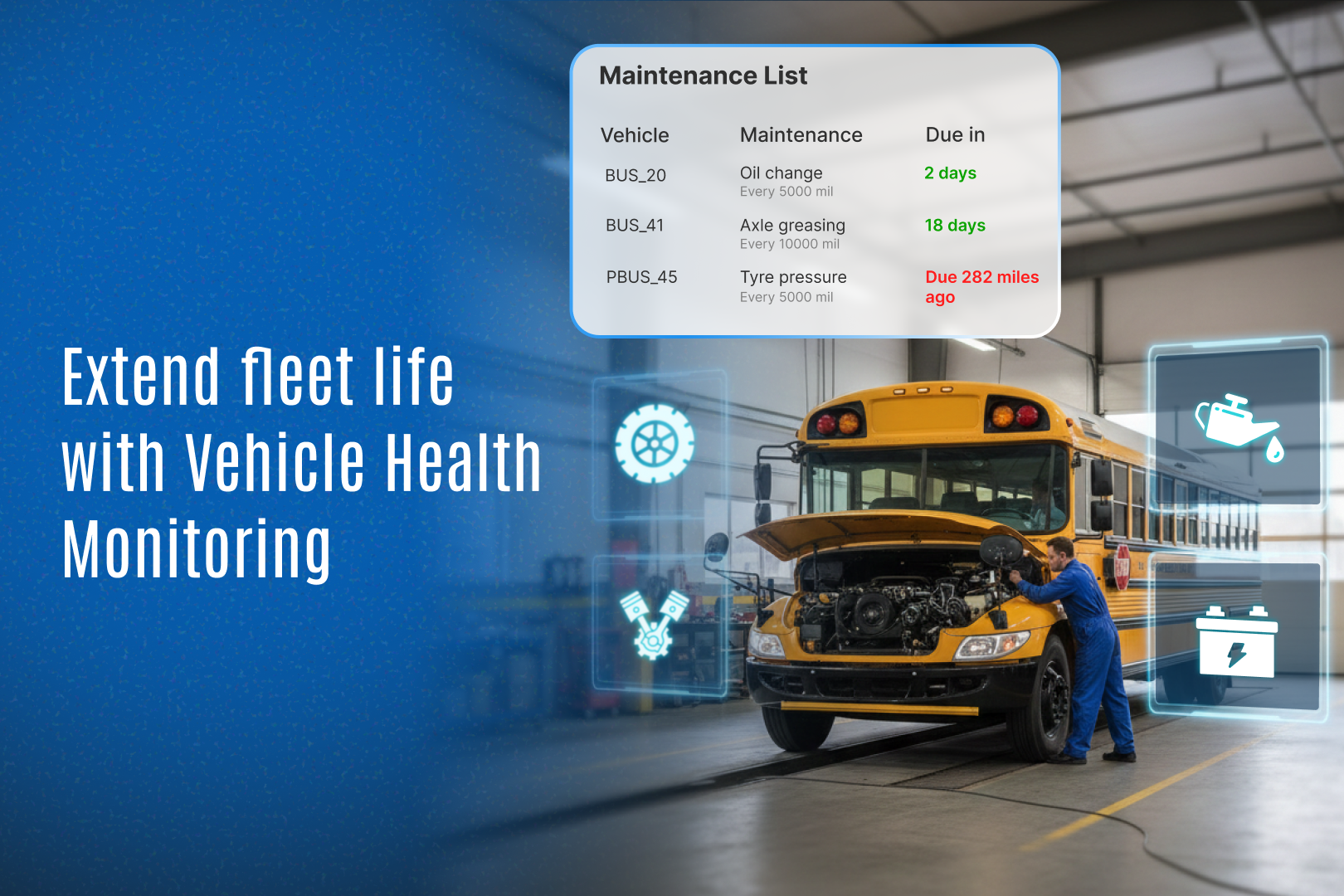

This is where Vehicle Health Monitoring is transforming fleet maintenance. By shifting from reactive and preventive maintenance to predictive maintenance, fleet operators can extend vehicle life, reduce downtime, and gain better control over operational costs. When high-quality MDVR hardware is combined with advanced tracking software like SmartBus, fleets gain a complete, 360-degree view of vehicle health enabling smarter and faster decisions.

What Is Vehicle Health Monitoring in Fleet Telematics?

Vehicle Health Monitoring refers to the continuous tracking and analysis of a vehicle’s mechanical and operational condition using telematics hardware and software.

Instead of relying on scheduled inspections or driver feedback, it uses real-time data to assess:

- Engine performance and load

- Battery health and voltage levels

- RPM and idling patterns

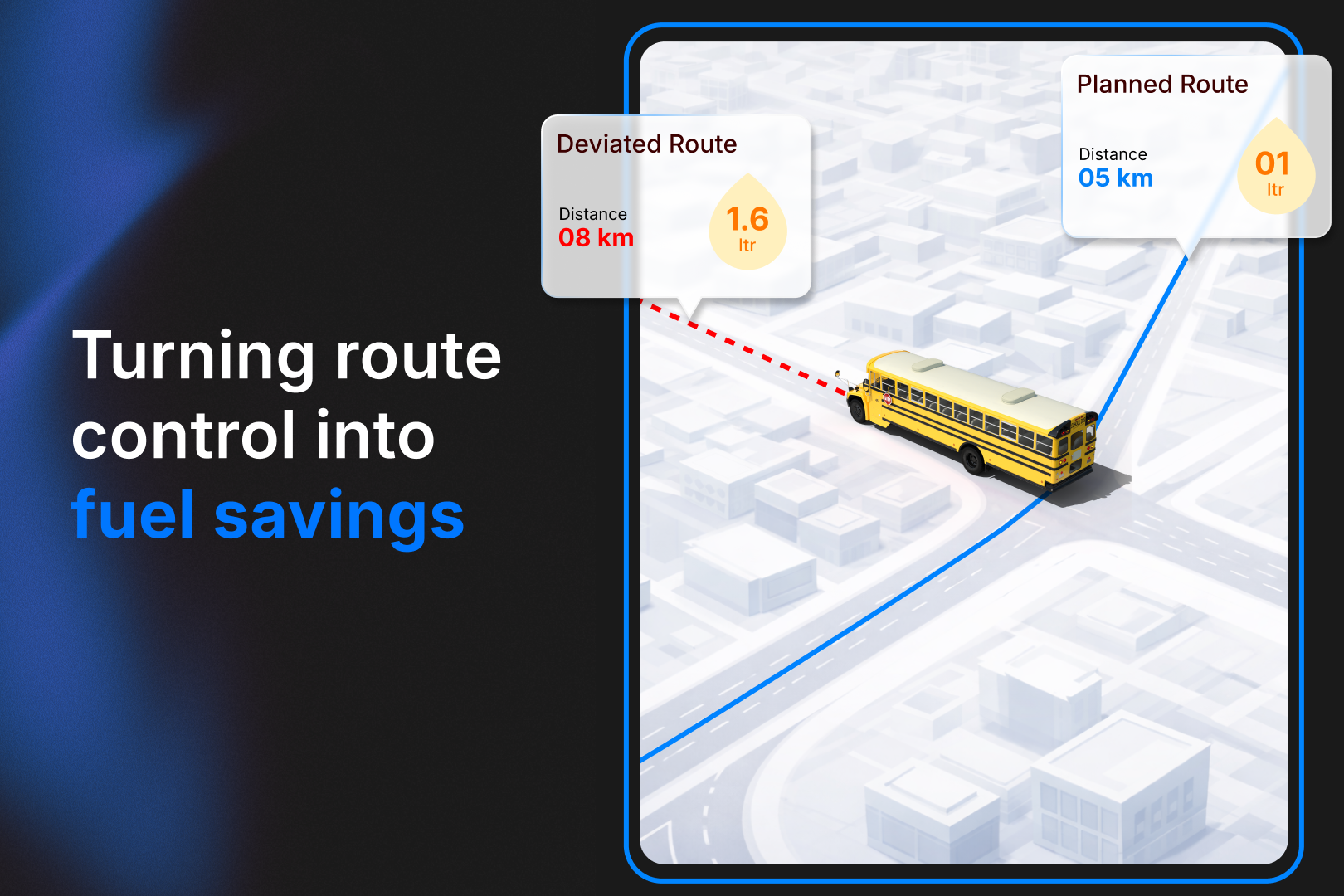

- Fuel efficiency trends

- Fault codes and system alerts

- Driver behavior impacting vehicle wear

This real-time visibility allows fleet managers to understand the actual condition of each vehicle, not just its service history.

Vehicle Health Monitoring vs Reactive Maintenance

Reactive maintenance follows a simple logic: repair the vehicle after a failure occurs. While common, this approach leads to:

- Unexpected breakdowns

- Route disruptions and service delays

- High emergency repair costs

- Reduced vehicle lifespan

- Increased safety risks

Vehicle Health Monitoring eliminates guesswork by identifying early warning signs before a breakdown happens. Instead of reacting to failures, fleets can plan maintenance activities based on real vehicle conditions.

Why Preventive Maintenance Alone Is No Longer Enough

Preventive maintenance improved fleet reliability by introducing scheduled servicing based on time or distance. However, it still has limitations:

- Vehicles may be serviced too early or too late

- Real driving behavior is ignored

- Developing issues between service cycles remain unnoticed

Vehicle Health Monitoring fills this gap by adding condition-based intelligence to traditional maintenance practices.

How Vehicle Health Monitoring Enables Predictive Maintenance

Predictive maintenance is the most advanced stage of fleet maintenance.

By continuously analyzing vehicle data, predictive systems can:

- Detect abnormal trends in engine temperature or RPM

- Identify battery degradation before failure

- Highlight driving patterns that accelerate component wear

- Predict maintenance needs based on historical data

For example, a gradual increase in engine temperature combined with aggressive driving behavior may indicate a cooling system issue. Vehicle Health Monitoring flags this early, allowing maintenance teams to act before serious damage occurs.

The Role of MDVR Hardware in Vehicle Health Monitoring

Accurate predictions depend on accurate data. This is why hardware quality is critical in Vehicle Health Monitoring.

Why High-Quality MDVR Hardware Matters

Enterprise-grade MDVR hardware ensures:

Reliable data capture in harsh operating conditions

Stable integration with vehicle sensors and Controller Area Network bus

Long-term durability with minimal hardware failures

Accurate correlation between vehicle performance and driver behavior

MDVRs are designed for commercial fleets where reliability, data accuracy, and uptime are non-negotiable. They act as a trusted data source for Vehicle Health Monitoring systems.

Turning Raw Data into Insights with Tracking Software

Hardware collects data but software transforms it into decisions.

An all in one school bus monitoring software like SmartBus plays a key role in Vehicle Health Monitoring by:

- Aggregating data from MDVRs, GPS devices, and sensors

- Analyzing trends instead of isolated incidents

- Providing easy-to-read dashboards for fleet managers

- Generating automated alerts for abnormal behavior

- Producing reports for maintenance planning and compliance

Vehicle Health Monitoring in Action

- MDVR records abnormal engine load patterns

- Software detects deviation from normal performance

- System generates an early warning alert

- Maintenance is scheduled proactively

- Vehicle avoids breakdown and extended downtime

This seamless flow from data to action defines effective predictive maintenance.

Achieving a 360-Degree View

When MDVR hardware is integrated with SmartBus tracking software, fleets gain a complete view of vehicle health:

Mechanical Health Monitoring

- Engine diagnostics

- Battery and voltage status

- Fault code visibility

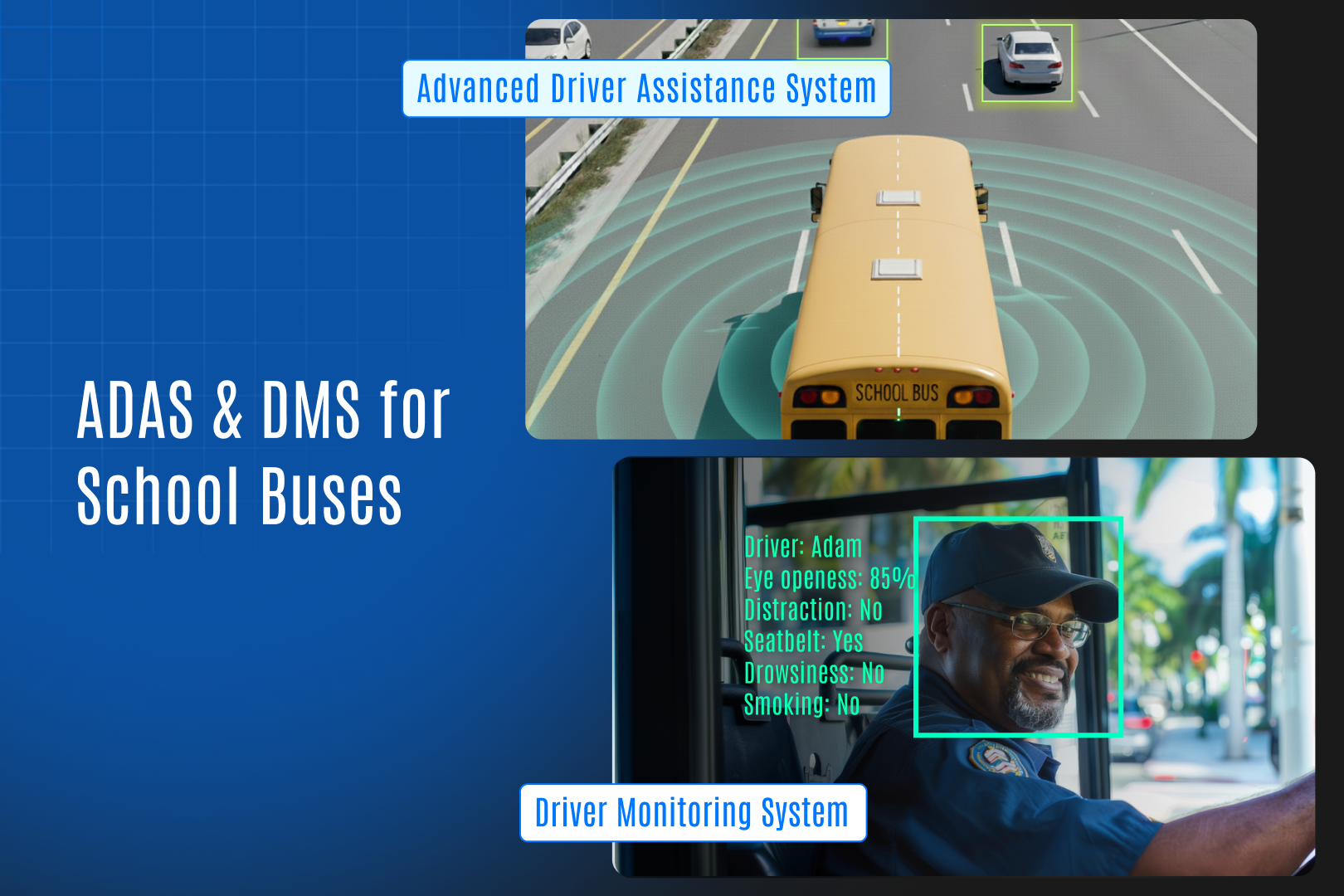

Driver Behavior Insights

- Harsh braking and acceleration

- Over-revving and excessive idling

- Driving habits impacting vehicle longevity

Operational Stress Analysis

- Route conditions

- Load frequency

- Stop-and-go intensity

Historical Performance Trends

- Maintenance history

- Failure patterns

- Component lifespan analysis

This holistic approach allows fleet managers to understand not just what failed, but why it failed.

How Vehicle Health Monitoring Extends Fleet Life

1. Early Issue Detection

Minor issues are resolved before they escalate into costly failures.

2. Reduced Wear and Tear

Driver behavior insights help reduce mechanical stress on vehicles.

3. Smarter Maintenance Scheduling

Maintenance is based on real vehicle condition, not assumptions.

4. Lower Total Cost of Ownership

Fewer breakdowns and emergency repairs mean predictable expenses.

5. Improved Asset Value

Well-maintained vehicles retain higher resale and operational value.

Why Vehicle Health Monitoring Matters for B2B Fleet Stakeholders

It creates new value for system integrators and ERP integrators:

- Advanced service offerings beyond basic tracking

- Deeper integration with enterprise systems

- Stronger differentiation in competitive markets

- Long-term customer retention through predictive insights

For fleet owners, it delivers operational control, safety improvements, and measurable ROI.

The Future of Fleet Maintenance Is Predictive

Fleet management is evolving from experience-based decisions to data-driven intelligence. It is no longer optional; it is becoming essential for fleets that want to remain competitive and profitable.

By combining reliable MDVR hardware with intelligent school fleet management software like SmartBus, fleets can move confidently from reactive maintenance to predictive maintenance.

Conclusion

Vehicle Health Monitoring is not just about knowing where a vehicle is, it is about understanding how healthy it is, how it is driven, and how long it can perform reliably.

Fleets that adopt Vehicle Health Monitoring today are not just reducing maintenance costs; they are extending fleet life, improving safety, and building sustainable operations for the future.

For fleet operators, system integrators, and technology partners, this shift represents a smarter, more resilient way to manage vehicles one insight at a time.