Cranes are critical in many industrial sectors, and their operations are inherently risky, requiring precise control. Tilt sensors are a game-changer for enhancing the safety and efficiency of crane operations.

Introduction

Challenges

Risk of Tipping: Cranes can tip if they are overloaded or if the load swings excessively.

Operational Downtime: Unsafe crane operations can lead to accidents, causing costly downtime.

Compliance with Safety Standards: Cranes must operate within strict safety regulations to prevent accidents.

Environmental Factors: Wind and other environmental factors can affect crane stability.

Challenges

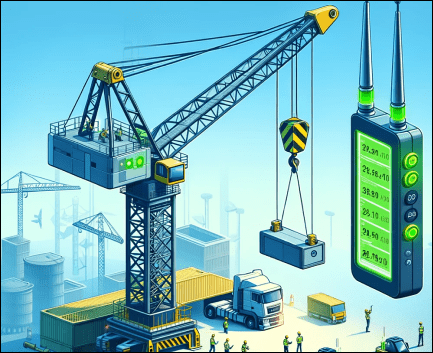

Solution

Tilt Sensor Implementation: Equip cranes with high-precision tilt sensors to provide accurate data on the boom’s position.

Real-Time Monitoring System: Integrate the tilt sensor data with a real-time monitoring system for continuous surveillance of crane operations.

Automated Alerts: Develop an alert system to notify operators when tilt angles exceed safe thresholds.

Data Analytics: Use historical tilt data to analyze and optimize crane operations and predict maintenance needs.

Results

Enhanced Safety: Significant reduction in the incidence of accidents due to over-tilting.

Operational Efficiency: Reduced downtime through proactive monitoring, leading to more efficient project timelines.

Regulatory Compliance: Assurance of adherence to safety regulations, avoiding fines and work stoppages.

Mitigation of Environmental Risks: Better preparedness for environmental factors affecting crane stability.